Effective inventory management is a critical aspect of successful field service management, as it directly impacts costs, efficiency, and customer satisfaction. By implementing best practices and leveraging technology, field service businesses can optimize their inventory processes, reduce expenses, and improve overall performance. In this article, we will explore various tips for enhancing inventory management in the field service industry.

Establishing an Effective Inventory Management System

A well-structured inventory management system is crucial for streamlining processes and ensuring accurate record-keeping. Here are some key components of an effective system:

- Centralized inventory tracking: Consolidate your inventory information into a single, centralized system to minimize errors and improve visibility.

- Accurate record-keeping: Maintain up-to-date and precise records of inventory levels, transactions, and locations to enable efficient decision-making.

- Regular inventory audits: Conduct periodic audits to verify the accuracy of inventory records and identify discrepancies or issues that need to be addressed.

Maintain up-to-date and precise records of inventory levels, transactions, and locations to enable efficient decision-making.

Optimizing Inventory Levels

Striking the right balance between safety stock and just-in-time inventory is essential for minimizing costs and ensuring that technicians have the parts and equipment they need when they need them. Consider the following tips for optimizing your inventory levels:

- Balancing safety stock and just-in-time inventory: Assess your business’s unique needs and risks to determine the appropriate level of safety stock, while also embracing just-in-time inventory practices to reduce carrying costs.

- Identifying and reducing excess stock: Regularly review inventory levels to identify surplus items and implement strategies to reduce excess stock, such as offering discounts or reevaluating reorder points.

- Managing slow-moving and obsolete items: Monitor inventory turnover rates and take proactive steps to address slow-moving or obsolete items, such as liquidating stock, negotiating returns with suppliers, or adjusting procurement strategies.

Leveraging Technology for Inventory Management

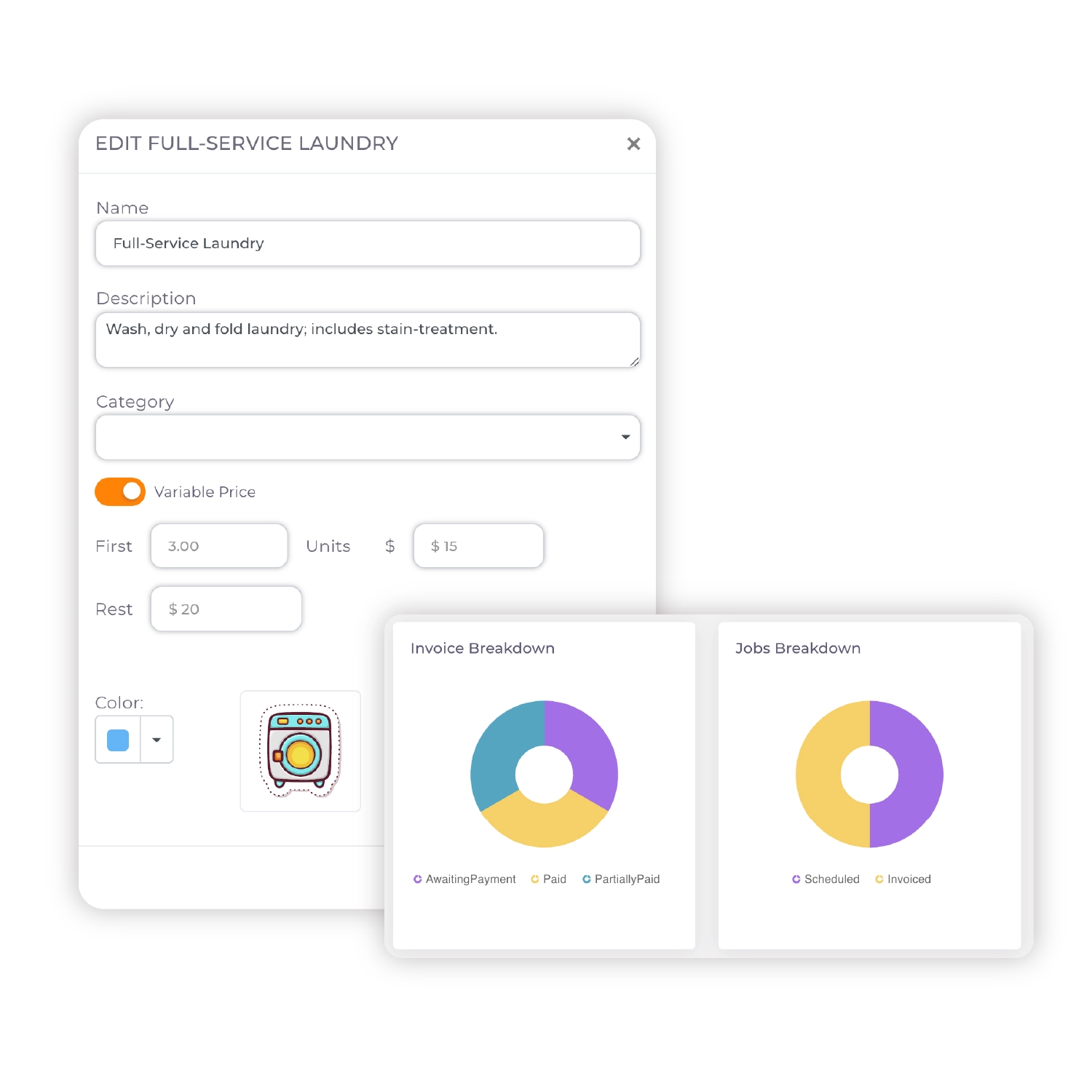

Field service management software and other technological tools can significantly enhance inventory management processes by automating tasks, improving accuracy, and providing real-time updates. Consider incorporating the following technologies into your inventory management strategy:

- Field service management software integration: Choose software that integrates seamlessly with your existing inventory management system, allowing for streamlined communication and data sharing. This functionality is provided by market leaders like ServiceDeck, IFS, and others.

- Barcode scanning and RFID tracking: Utilize barcode scanning and RFID tracking technologies to automate inventory tracking, reduce errors, and improve efficiency.

- Real-time inventory updates and reporting: Implement solutions that provide real-time inventory updates and reporting, enabling you to make informed decisions and respond quickly to changes in demand.

Streamlining the Supply Chain

An efficient supply chain is vital for effective inventory management. By building strong relationships with suppliers and vendors and optimizing procurement processes, businesses can minimize costs and improve inventory control. Consider the following strategies for streamlining your supply chain:

- Building relationships with suppliers and vendors: Cultivate strong partnerships with suppliers and vendors to negotiate better pricing, improve communication, and ensure reliable access to inventory.

- Implementing demand forecasting and planning: Employ demand forecasting techniques to anticipate future inventory needs, allowing for more efficient procurement and inventory management.

- Evaluating and optimizing the procurement process: Regularly review and refine your procurement process to identify areas for improvement and minimize costs.

Training and Empowering Field Technicians

Field technicians play a critical role in inventory management, as they are responsible for using, tracking, and replenishing stock. By providing education on inventory management best practices and encouraging accountability, businesses can empower their technicians to contribute to effective inventory control. Consider the following tips for training and empowering field technicians:

- Providing education on inventory management best practices: Offer training and resources to help technicians understand the importance of inventory management and the best practices for maintaining accurate records.

- Encouraging accountability and ownership: Foster a culture of accountability and ownership by clearly communicating expectations for inventory management and holding technicians responsible for their actions.

- Leveraging mobile technology: Equip field technicians with mobile devices and apps that provide real-time access to inventory information, and enable them to update records and request replenishments from the field.

- Implementing feedback loops: Encourage technicians to provide feedback on inventory processes and challenges, and use their insights to continually improve and adapt your inventory management strategies.

Continuously Monitoring and Improving Inventory Management

To achieve long-term success in inventory management, it is essential to continuously monitor performance and identify areas for improvement. By tracking key performance indicators (KPIs) and analyzing trends, businesses can make data-driven decisions and refine their inventory strategies. Consider the following tips for ongoing monitoring and improvement:

- Tracking KPIs: Monitor KPIs such as inventory turnover rates, stock-out incidents, and carrying costs to evaluate the effectiveness of your inventory management strategies.

- Analyzing trends and identifying areas for improvement: Use data and analytics to identify trends, inefficiencies, and opportunities for improvement, and adjust your inventory management strategies accordingly.

- Implementing a continuous improvement mindset: Foster a culture of continuous improvement and encourage all team members to actively participate in identifying and addressing inventory management challenges.

Conclusion

Effective inventory management is crucial for reducing costs and improving efficiency in the field service industry. By establishing an effective inventory management system, optimizing inventory levels, leveraging technology, streamlining the supply chain, training and empowering field technicians, and continuously monitoring and improving inventory management, field service businesses can enhance their overall performance and deliver exceptional service to their customers.

Investing in field service management software and other technological tools that support these best practices can further improve operations and drive business growth. As the field service industry continues to evolve, embracing technology and adopting data-driven inventory management strategies will be essential for companies looking to stay competitive and deliver top-notch service.

What our clients say

Take the next step

Explore ServiceDeck or book a demo to see how it can streamline your business and answer your questions.

Create your profile

Sign up and tell us a bit about your business.

Book your setup call

Schedule a quick onboarding session with our team.

2 Comments